Equipment Used

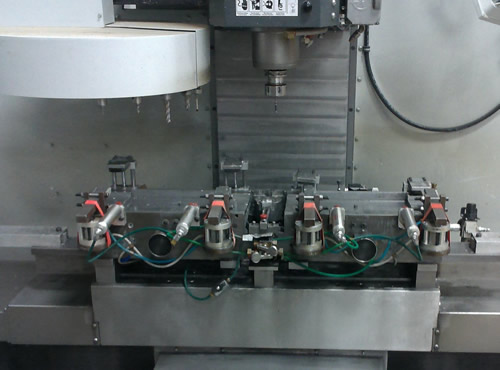

- HAAS VF2 w/ Probe

Expertise

- Machining

Technical Specifications

Overall Part Dimensions: 2.000″ x 9.000″ x Variety of Lengths

Tightest Tolerances: +/– .010″

Materials Used

- Customer-supplied Extrusions

In Process Inspection / Testing

- CMM

Industry

Window and Door

Volume

15,000+ EAU

Delivery / Turn-Around Time

2-3 Days

Location

Eastern Iowa

Product Name

Sill Plate

Value Proposition

- Increased Quality

- Fewer Rejections

- Ability to use otherwise “bad” raw material.

Summary

A Window and Door producer was having issues with the extrusions used in producing their door sills varying from batch to batch. Die Makers Mfg setup a Haas VF-2 vertical CNC 3 Axis Mill with a spindle probe to pick up and adjust coordinate offsets to provide next to perfect machining on varying types of extrusions.