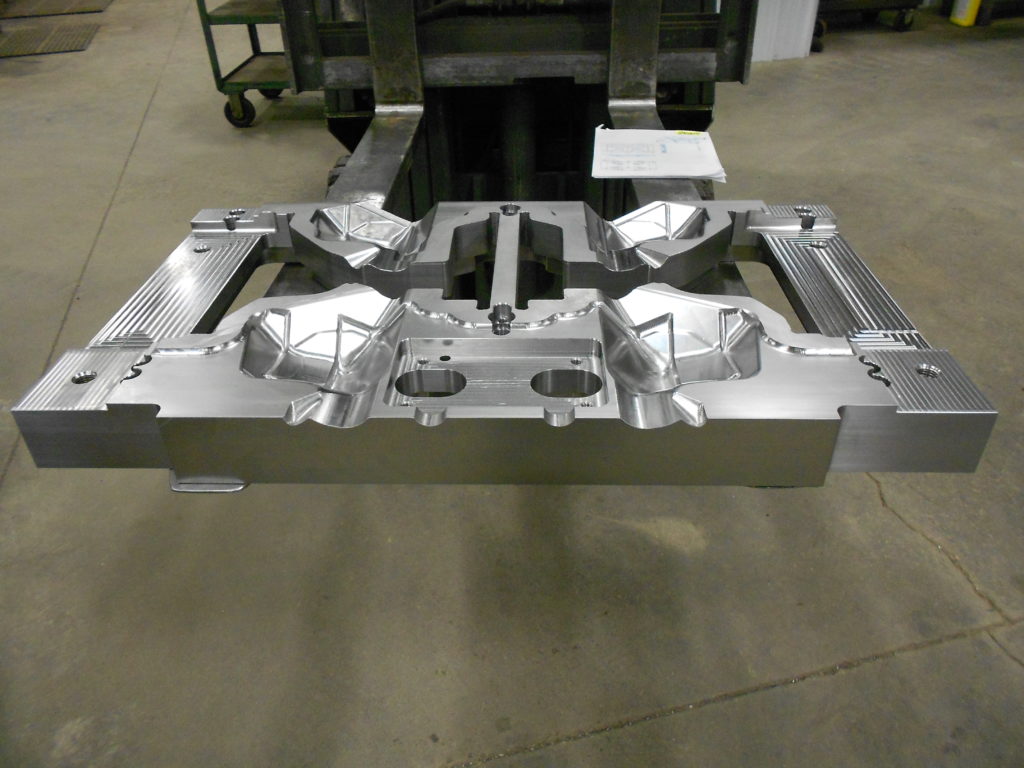

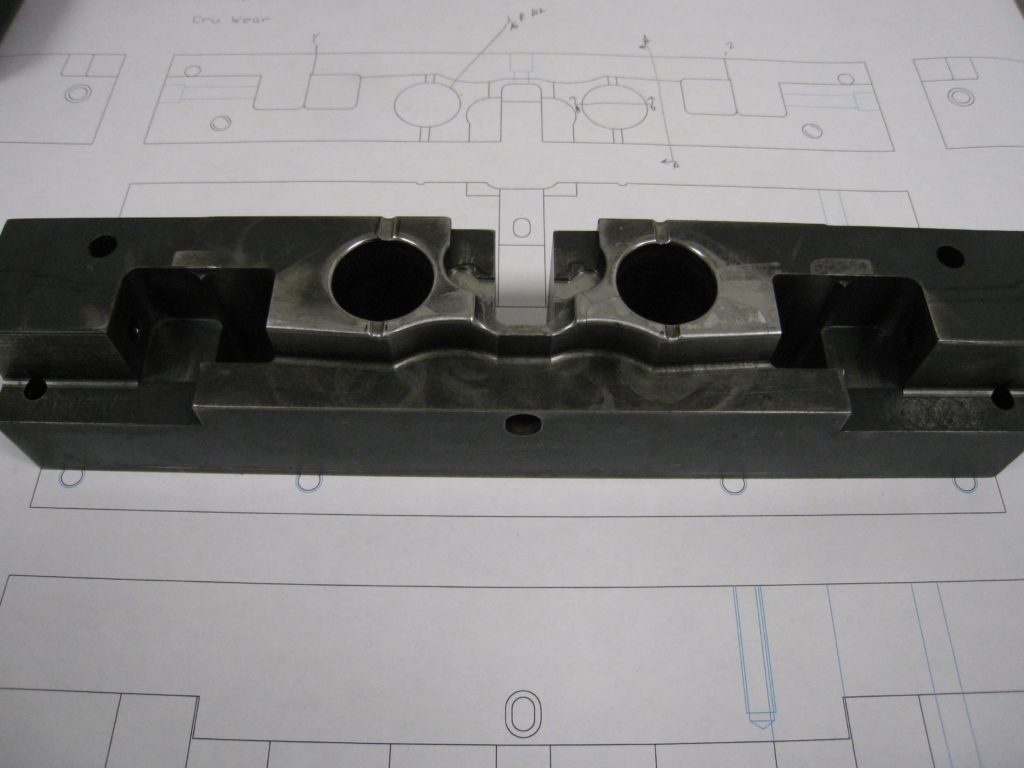

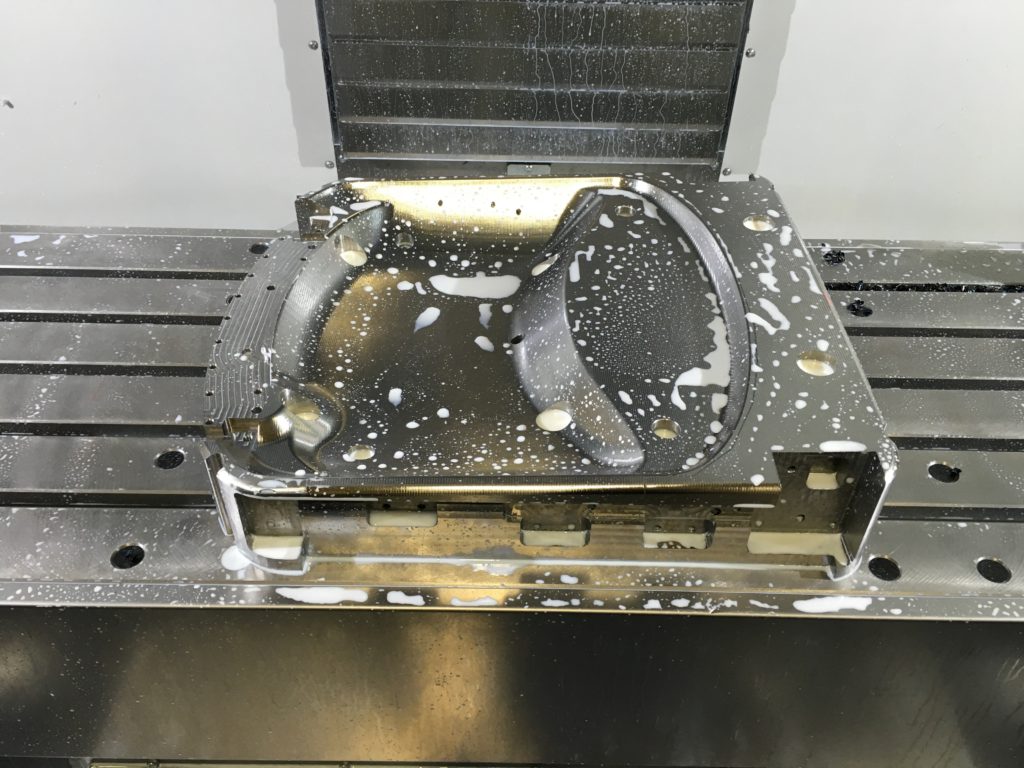

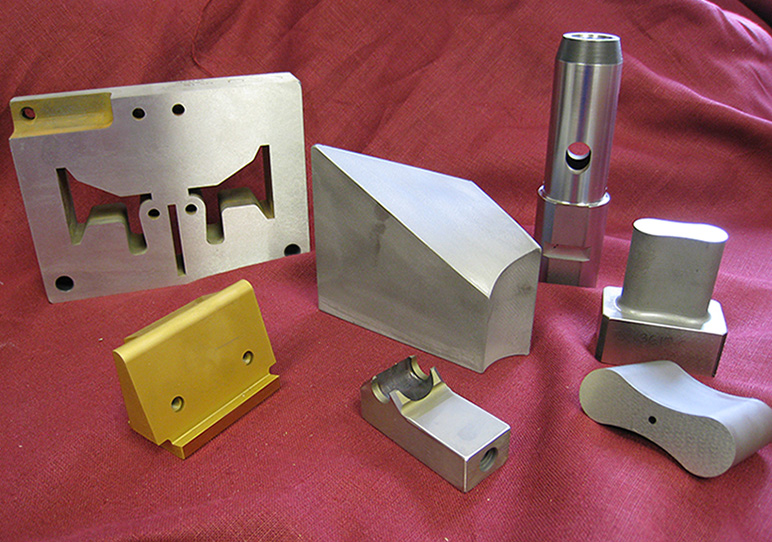

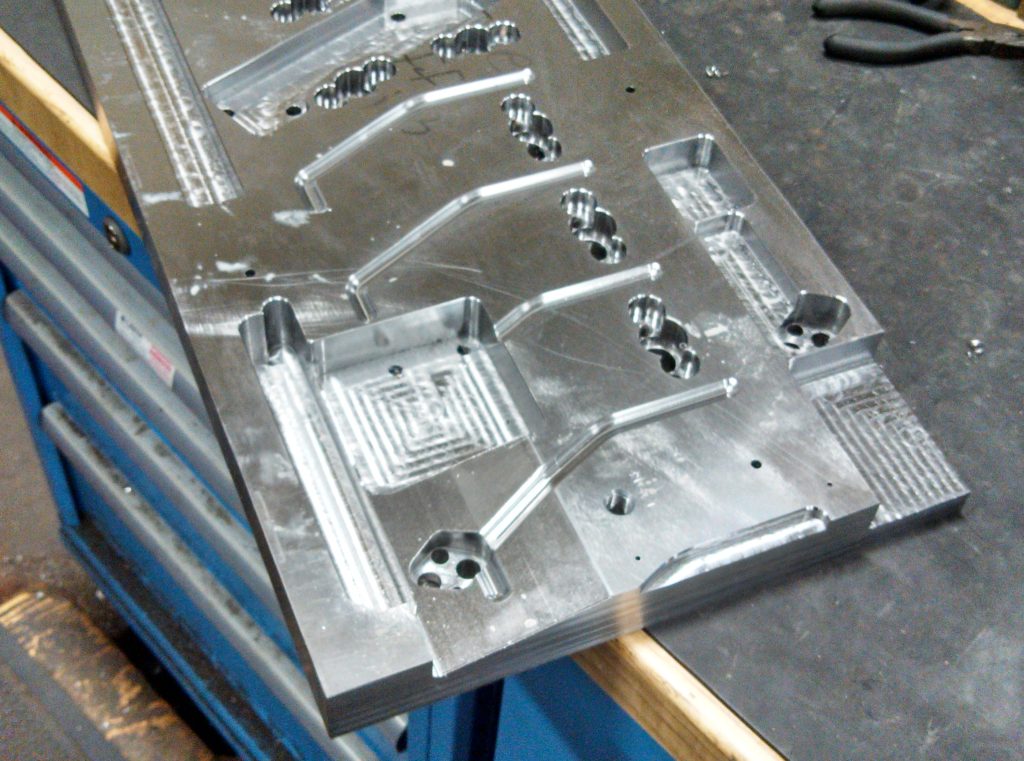

Die Makers can quickly remanufacture and replace damaged or worn-out die components. Our experienced tool makers and machinists utilize our full-service tool room and state-of-the-art equipment to provide a quick turn around on your components. Our Wire EDM and CNC machinists can accurately reproduce your components to your specifications. Additionally, we can provide in-house TIG welding and heat treating services. Therefore, there’s no need to wait for these services to be outsourced.

We have a coordinate measuring machine (CMM). Therefore, we are able to reverse engineer die components if component CAD or prints are not available. We specialize in replacement stamping die components that are complex. Our team can handle a high degree of accuracy, within 0.0002 inches.

Die Preventative Maintenance

Die Makers excels in the preventative and ongoing maintenance of metal stamping dies and tooling. We want to help you continue to produce accurate parts within your specifications. And without costly downtime. Our tool makers can sharpen and recondition your die which will extend the life of the die.

Stamping Die Repair

We repair all types of metal stamping dies and tooling. Our team can remanufacture your die if updates or changes are needed. We stock tool steel so that we are prepared to begin die repairs immediately. Therefore, we do not have a time-consuming wait for supplies. We offer reverse engineering as well as complete in-house machining services, including TIG welding and heat treating.