In addition to supporting our die making and metal stamping operations, our wire EDM department also provides contract wire EDM services for parts in large or small volume. Our expert machinists use state-of-the-art equipment to meet or exceed our clients’ high quality standards. We have experience machining parts and components with a wide variety of materials. We can provide a fast turnaround on prototypes, one-off parts, full production runs and die components, so contact us for a competitive quote.

Wire EDM a Variety of components

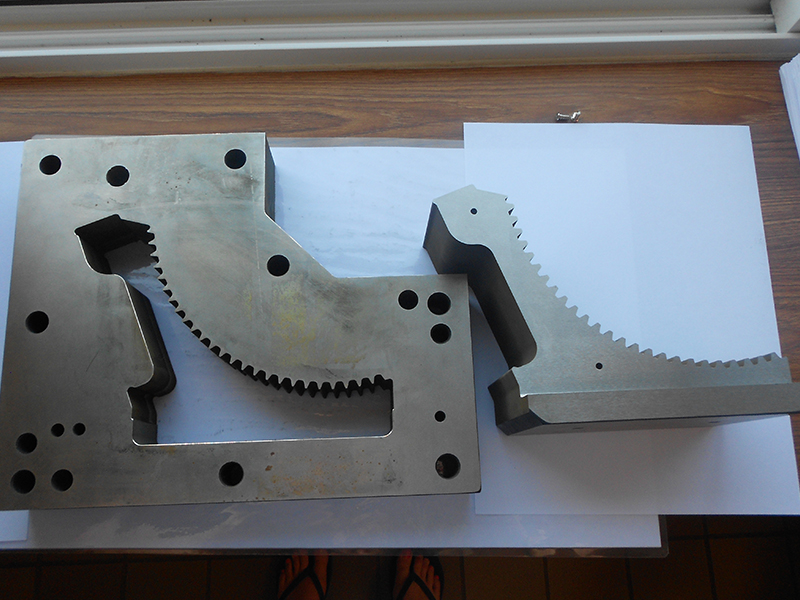

We have experience providing wire EDM services for a wide variety of components and parts including:

- Die components

- Punches

- Die blocks

- Die inserts

- Strippers

- Punch holders

- Form blocks and inserts

Blocks can be made complete in our shop, or we will EDM your furnished blocks.

Variety of Materials

We have experience wire EDM machining delicate or brittle parts with complex shapes in a wide variety of conductive materials including:

- Aluminum

- Carbon Steel

- Stainless Steel

- Brass

- Copper

- Bronze

- Carbide

- All Tool Steels

Others: Please let us know your material, tolerance and surface finishing requirements.

State-of-the-art equipment

Our expert machinists use state-of-the-art equipment so we can exceed our clients’ high quality standards for even the most complex parts. As a result, we can produce close tolerance parts (+/- 0.0005” or better). Our Wire EDM machines can handle parts in lengths up to 23.600”, widths up to 15.750” and heights up to 13.050”.

We can also meet your surface finish requirements by increasing the number of passes or skims (8 RA surface finish). Our machinists can also accommodate EDM hole drilling as small .032” diameter and as deep as 10.000”. Die Makers continues to reinvest in the latest equipment so our clients receive the lowest cost per part, highest quality and on time delivery.